What is the installation method of PERT EVOH Pipe?

Leave a message

When it comes to modern plumbing systems, PERT EVOH pipes have emerged as a top choice for their exceptional performance and durability. As a leading supplier of PERT EVOH pipes, I'm excited to share with you the comprehensive installation methods for these innovative pipes.

Understanding PERT EVOH Pipes

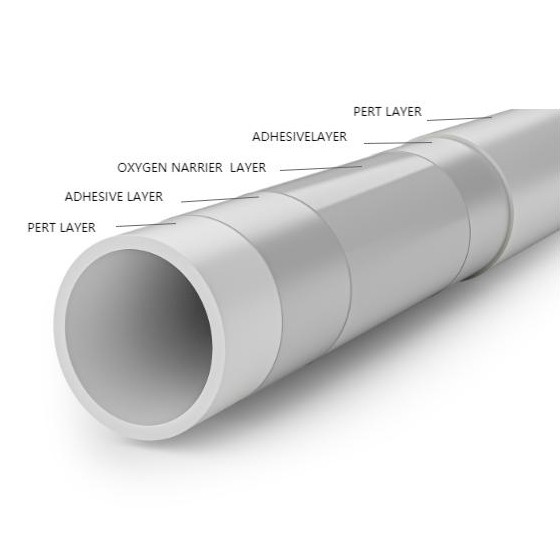

Before delving into the installation process, it's essential to understand what PERT EVOH pipes are. PERT (Polyethylene of Raised Temperature resistance) is a high - performance polyethylene material that can withstand relatively high temperatures. EVOH (Ethylene - Vinyl Alcohol Copolymer) is an excellent oxygen barrier material. Combining these two materials, PERT EVOH pipes offer not only good heat resistance but also remarkable oxygen barrier properties, which prevent oxygen from penetrating the pipes and causing corrosion in the heating system.

We offer two main types of PERT EVOH pipes: PERT/EVOH Pipe 5 Layers and PERT/EVOH Pipe 3 Layers. The 5 - layer pipes usually have a more complex structure, providing enhanced oxygen barrier performance and mechanical strength. The 3 - layer pipes, on the other hand, are more cost - effective while still maintaining good overall performance.

Tools and Materials Required

To install PERT EVOH pipes, you'll need the following tools and materials:

- Pipe cutters: A sharp pipe cutter is essential for making clean and accurate cuts on the pipes. Manual or electric pipe cutters can be used depending on the volume of work and personal preference.

- Pipe fittings: Appropriate fittings such as elbows, tees, couplings, and valves are required to connect the pipes and create the desired plumbing layout. Make sure the fittings are made of compatible materials with the PERT EVOH pipes.

- Welding machine (for heat - fusion joints): If you're using heat - fusion joints, a high - quality welding machine is necessary. The welding machine should be able to provide a stable and accurate temperature for a proper fusion.

- Measuring tools: Tape measures, levels, and angle finders are needed to ensure the pipes are installed in the correct position and alignment.

- Marking tools: Pencils or markers are used to mark the pipes for cutting and fitting.

Installation Steps

Step 1: Planning and Design

Before starting the installation, it's crucial to plan the plumbing layout carefully. Consider the location of fixtures, the direction of water flow, and any potential obstacles. Draw a detailed diagram of the system to ensure all connections and components are accounted for. This step will save you time and materials in the long run.

Step 2: Cutting the Pipes

Use the pipe cutter to cut the PERT EVOH pipes to the desired length. Make sure the cut is perpendicular to the axis of the pipe. After cutting, remove any burrs or debris from the cut end using a deburring tool. This will ensure a smooth and proper connection with the fittings.

Step 3: Preparing the Fittings

If you're using heat - fusion joints, clean the surfaces of the pipe ends and the fittings with a clean cloth to remove any dirt, grease, or moisture. This is crucial as any contaminants can affect the quality of the fusion joint.

Step 4: Making Heat - Fusion Joints

- Heating the pipe and fitting: Insert the pipe end and the fitting into the appropriate heating elements of the welding machine. The heating time depends on the diameter of the pipe and the type of welding machine. Follow the manufacturer's instructions carefully to ensure the correct heating time.

- Fusing the pipe and fitting: Once the pipe and fitting are heated to the appropriate temperature, quickly and steadily insert the pipe into the fitting until it reaches the marked depth. Hold the pipe and fitting in place for a short period to allow the material to cool and solidify. Do not move or rotate the pipe during this cooling process.

Step 5: Installing the Pipes

- Mounting the pipes: Use brackets or hangers to support the pipes along their length. The spacing between the supports depends on the diameter of the pipe and the installation environment. Generally, smaller diameter pipes require more frequent supports.

- Connecting the pipes: Connect the pipes using the prepared fittings and heat - fusion joints. Make sure all joints are tight and leak - free. Check the alignment of the pipes regularly during the installation process to ensure a straight and efficient plumbing system.

Step 6: Testing the System

After the installation is complete, it's essential to test the plumbing system for leaks. Close all the faucets and valves, and then fill the system with water. Check all the joints and connections for any signs of leakage. If a leak is detected, mark the location and repair it immediately. Once the system has been tested and found to be leak - free, you can proceed to use the plumbing system.

Tips for a Successful Installation

- Follow the manufacturer's instructions: Different brands of PERT EVOH pipes may have slightly different installation requirements. Always follow the manufacturer's instructions for cutting, heating, and joining the pipes.

- Maintain a clean working environment: Keep the work area clean and free of debris. This will prevent contaminants from getting into the pipes and affecting the performance of the system.

- Train your installers: If you're hiring installers, make sure they are trained in the proper installation methods for PERT EVOH pipes. A well - trained installer can ensure a high - quality installation and minimize the risk of problems.

Conclusion

Installing PERT EVOH pipes requires careful planning, the right tools, and proper techniques. By following the steps outlined above, you can ensure a successful installation of your plumbing system. As a reliable PERT EVOH pipe supplier, we are committed to providing high - quality products and technical support to our customers. If you're interested in purchasing PERT EVOH pipes for your project or have any questions about the installation process, please don't hesitate to contact us. We look forward to discussing your needs and helping you find the best solutions for your plumbing requirements.

References

- Technical manuals of PERT EVOH pipes from leading manufacturers.

- Industry standards and guidelines for plumbing system installation.