What is the impact of sediment in water on PE - Xa Pipe NSF?

Leave a message

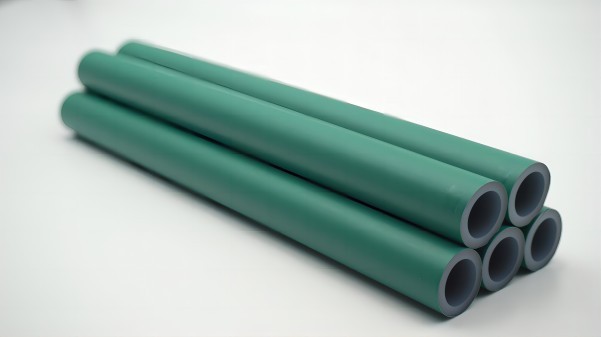

Sediment in water is a common issue that can have various impacts on different types of pipes, including PE - Xa pipes certified under NSF standards. As a supplier of PE - Xa Pipe NSF, I have witnessed firsthand the effects of sediment on these pipes and understand the importance of addressing this concern for our customers.

Understanding Sediment in Water

Sediment in water can consist of a wide range of materials, such as sand, silt, clay, rust, and other particulate matter. These particles can enter the water supply from various sources, including natural erosion, construction activities, and aging water infrastructure. When water containing sediment flows through pipes, it can cause several problems that may affect the performance and longevity of the pipes.

Impact on Flow Capacity

One of the primary impacts of sediment in water on PE - Xa Pipe NSF is the reduction of flow capacity. As sediment accumulates inside the pipes, it can form a layer on the inner surface, narrowing the diameter of the pipe. This reduction in diameter restricts the flow of water, leading to decreased water pressure and flow rate at the fixtures. For example, in a plumbing system, low water pressure can result in weak showers, slow - filling toilets, and inefficient operation of appliances that rely on water flow.

Over time, the build - up of sediment can become significant, causing a substantial reduction in the pipe's flow capacity. This not only affects the comfort and convenience of the end - users but can also lead to increased energy consumption as pumps need to work harder to maintain the desired water pressure.

Abrasion and Wear

Sediment particles in water can act as abrasives, causing wear and tear on the inner surface of PE - Xa pipes. As the water flows through the pipes, the sediment particles rub against the pipe wall, gradually wearing it down. This abrasion can weaken the pipe structure, making it more susceptible to leaks and failures.

In areas with high sediment content in the water, the rate of abrasion can be accelerated. The constant rubbing of sediment particles can also cause micro - scratches on the pipe surface, which can serve as starting points for corrosion and other forms of damage. This can ultimately lead to premature failure of the pipes, resulting in costly repairs and replacements.

Impact on Water Quality

The presence of sediment in water can also have implications for water quality. Sediment can carry various contaminants, such as bacteria, heavy metals, and organic matter. When the sediment accumulates in the pipes, these contaminants can be trapped and multiply, potentially posing a health risk to the users.

For example, bacteria can grow in the moist environment created by the sediment build - up, leading to the formation of biofilms. These biofilms can release harmful substances into the water, affecting its taste, odor, and safety. In addition, sediment can also cause discoloration of the water, making it unappealing to the end - users.

Effect on NSF Certification

NSF certification for PE - Xa pipes ensures that they meet certain standards for safety and performance. The presence of sediment in water can potentially affect the pipe's ability to maintain these standards. For instance, if the abrasion caused by sediment leads to the release of harmful substances from the pipe material, it may violate the NSF requirements.

Moreover, the build - up of sediment can create conditions that promote the growth of bacteria and other microorganisms, which may also compromise the pipe's compliance with NSF standards related to water quality. As a supplier of PE - Xa Pipe NSF, we are committed to ensuring that our pipes continue to meet these standards even in challenging water conditions.

Preventive Measures

To mitigate the impact of sediment in water on PE - Xa Pipe NSF, several preventive measures can be taken. One of the most effective ways is to install sediment filters at the point of entry of the water supply. These filters can remove a significant portion of the sediment particles before they enter the pipes, reducing the risk of build - up and abrasion.

Regular maintenance of the plumbing system is also crucial. This includes flushing the pipes periodically to remove any accumulated sediment. Additionally, monitoring the water quality and sediment levels can help in detecting potential issues early and taking appropriate action.

Our Role as a Supplier

As a supplier of PE - Xa Pipe NSF, we understand the importance of providing high - quality pipes that can withstand the challenges posed by sediment in water. Our PE - Xa pipes are designed with features that enhance their resistance to abrasion and sediment build - up.

We also offer comprehensive support to our customers, including advice on proper installation, maintenance, and the selection of appropriate filtration systems. By working closely with our customers, we can ensure that our pipes perform optimally and meet their expectations in terms of durability and water quality.

If you are interested in learning more about our PE - Xa Pipe Watermark, which is designed to provide reliable performance even in the presence of sediment, or our PE - Xa Pipe for Plumbing Pipe and PEX Pipe for Water Supply, we encourage you to reach out to us. We are always ready to discuss your specific requirements and provide you with the best solutions for your plumbing needs. Whether you are a contractor, a building owner, or a distributor, we look forward to the opportunity to work with you and help you achieve a high - quality plumbing system.

References

- American Water Works Association. (2019). Water Quality and Treatment: A Handbook of Community Water Supplies. McGraw - Hill.

- National Sanitation Foundation. (2020). NSF Standards for Drinking Water System Components. NSF International.

- Pipe Fabrication Institute. (2018). Guide to Pipe Materials and Applications. PFI.