What is the fatigue resistance of pex 32mm pipes?

Leave a message

What is the fatigue resistance of PEX 32mm pipes?

As a supplier of PEX 32mm pipes, I've often been asked about the fatigue resistance of these pipes. Fatigue resistance is a crucial property, especially when it comes to long - term use in various applications. In this blog, I'll delve into what fatigue resistance means for PEX 32mm pipes, the factors affecting it, and why it matters in real - world scenarios.

Understanding Fatigue Resistance

Fatigue resistance refers to a material's ability to withstand repeated loading and unloading cycles without failing. In the context of PEX 32mm pipes, this means the pipe's capacity to endure the constant pressure changes, temperature fluctuations, and mechanical stresses that occur during normal use. For example, in a plumbing system, water flow starts and stops, causing pressure variations. Additionally, changes in water temperature, especially in hot - water supply systems, can subject the pipes to thermal expansion and contraction.

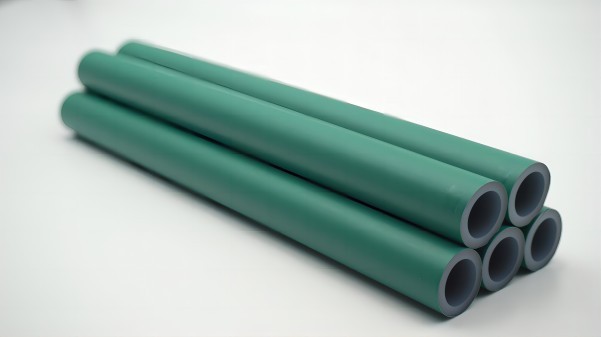

PEX, or cross - linked polyethylene, is a type of plastic that has been chemically or physically modified to create cross - links between the polymer chains. This cross - linking enhances the material's mechanical properties, including its fatigue resistance. Compared to traditional non - cross - linked polyethylene pipes, PEX pipes can better handle the cyclic stresses associated with regular use.

Factors Affecting the Fatigue Resistance of PEX 32mm Pipes

Cross - linking Method

There are different methods of cross - linking PEX, namely PEX - a, PEX - b, and PEX - c. PEX - a, which uses the peroxide method, generally offers the highest degree of cross - linking. This results in a more uniform and dense network of cross - links, providing better fatigue resistance. For instance, PE - Xa Pipe for Plumbing Pipe made using the PEX - a method can withstand a greater number of stress cycles before showing signs of failure.

Temperature

Temperature plays a significant role in the fatigue resistance of PEX 32mm pipes. Higher temperatures can soften the polymer, reducing its stiffness and strength. As a result, the pipe may be more prone to fatigue under cyclic loading at elevated temperatures. On the other hand, extremely low temperatures can make the pipe more brittle, also increasing the risk of fatigue failure. Therefore, it's essential to select PEX pipes that are suitable for the specific temperature range of the intended application.

Pressure

The pressure inside the pipes is another critical factor. Higher operating pressures increase the stress on the pipe walls. PEX 32mm pipes need to be designed to handle the maximum pressure that will be encountered in the system. If the pressure exceeds the pipe's rated capacity, the fatigue life of the pipe can be significantly reduced.

Chemical Environment

The chemical composition of the fluid flowing through the pipes can also affect fatigue resistance. Some chemicals may react with the PEX material, causing it to degrade over time. This degradation can weaken the pipe and make it more susceptible to fatigue failure. For example, certain solvents or aggressive cleaning agents can have a negative impact on the pipe's integrity.

Importance of Fatigue Resistance in Real - World Applications

Plumbing Systems

In residential and commercial plumbing systems, PEX 32mm pipes are commonly used for water supply. These pipes are subject to daily cycles of water flow, pressure changes, and temperature variations. A pipe with good fatigue resistance ensures a long - lasting and reliable plumbing system. For example, in a multi - story building, the pipes need to withstand the pressure differences between the upper and lower floors. PEX Pipe for Water Supply with high fatigue resistance can prevent leaks and failures, reducing maintenance costs and inconvenience for the building occupants.

Radiant Heating Systems

PEX 32mm pipes are also widely used in radiant heating systems. In these systems, hot water circulates through the pipes to heat the floor or other surfaces. The pipes are exposed to repeated heating and cooling cycles, which can cause thermal stress. Fatigue - resistant PEX pipes can handle these thermal cycles without cracking or leaking, ensuring the efficient operation of the heating system.

Testing and Standards for Fatigue Resistance

To ensure the quality and fatigue resistance of PEX 32mm pipes, various testing methods and standards have been established. These tests simulate the real - world conditions that the pipes will encounter, such as pressure cycling, temperature cycling, and chemical exposure. For example, the ASTM F876 standard specifies the requirements for PEX tubing used in water - based radiant heating and cooling systems, including tests for burst pressure, hydrostatic pressure, and accelerated aging.

Manufacturers typically conduct these tests on their products to ensure compliance with the relevant standards. By choosing PEX 32mm pipes from a reputable supplier, customers can be confident that the pipes have been tested and meet the necessary quality requirements.

Compatibility with Fittings

The fatigue resistance of PEX 32mm pipes is also influenced by their compatibility with fittings. When connecting the pipes to other components in the system, such as PPSU Tee, a proper and secure connection is essential. Incompatible fittings can create stress concentrations at the connection points, increasing the risk of fatigue failure. Therefore, it's important to use fittings that are specifically designed for PEX pipes and are recommended by the pipe manufacturer.

How Our PEX 32mm Pipes Excel in Fatigue Resistance

As a PEX 32mm pipe supplier, we take pride in offering products with excellent fatigue resistance. Our pipes are made using high - quality raw materials and advanced cross - linking technology. We conduct rigorous quality control tests to ensure that each pipe meets or exceeds the industry standards for fatigue resistance.

We also provide a wide range of fittings that are fully compatible with our PEX 32mm pipes. This ensures a seamless connection and reduces the risk of stress - related failures. Whether you're installing a new plumbing system or a radiant heating system, our PEX 32mm pipes are a reliable choice.

Contact Us for Your PEX 32mm Pipe Needs

If you're in the market for PEX 32mm pipes with high fatigue resistance, we're here to help. Our team of experts can provide you with detailed information about our products, including their performance characteristics and installation requirements. We can also assist you in selecting the right pipes and fittings for your specific application.

Contact us today to start a discussion about your PEX 32mm pipe procurement. We look forward to working with you to ensure the success of your project.

References

- ASTM International. (2023). ASTM F876 - Standard Specification for Crosslinked Polyethylene (PEX) Tubing.

- European Committee for Standardization. (2022). EN 12813:2022 - Plastics piping systems for hot and cold water installations - Crosslinked polyethylene (PE - X) - Specifications for pipes.

- Pipe Manufacturers Association. (2021). Technical Report on Fatigue Resistance of Plastic Pipes.