What is the anti - freezing performance of PERT EVOH Pipe?

Leave a message

As a supplier of PERT EVOH pipes, I've witnessed firsthand the growing demand for high - performance piping solutions in various industries, especially in regions with cold climates. One of the most critical aspects of these pipes is their anti - freezing performance. In this blog, I'll delve into what makes PERT EVOH pipes stand out in terms of withstanding freezing conditions.

Understanding PERT EVOH Pipes

PERT (Polyethylene of Raised Temperature resistance) is a type of polyethylene known for its excellent thermal stability, flexibility, and long - term hydrostatic strength. EVOH (Ethylene - Vinyl Alcohol copolymer) is a high - performance barrier resin that provides exceptional oxygen barrier properties. When combined, PERT EVOH pipes offer a unique set of characteristics that make them suitable for a wide range of applications, including heating, cooling, and potable water systems.

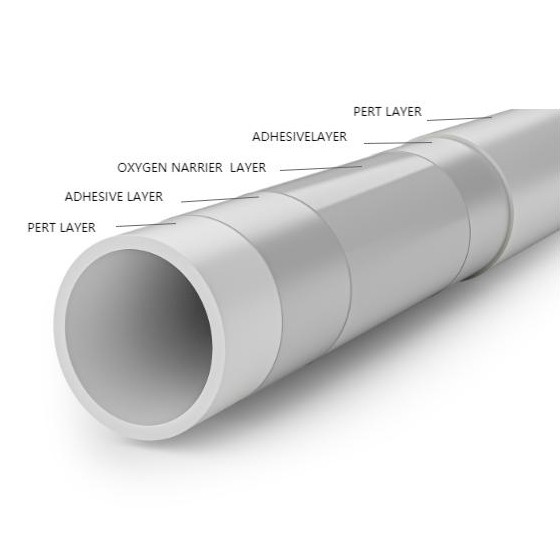

We offer two main types of PERT EVOH pipes: PERT/EVOH Pipe 3 Layers and PERT/EVOH Pipe 5 Layers. The 3 - layer pipes consist of an inner and outer PERT layer with an EVOH layer in the middle, while the 5 - layer pipes have additional adhesive layers between the PERT and EVOH layers for enhanced bonding.

Anti - Freezing Mechanisms of PERT EVOH Pipes

Material Flexibility

PERT is a flexible material. When water inside the pipe freezes and expands, the flexible nature of PERT allows the pipe to deform slightly without cracking. Unlike rigid pipes that are prone to bursting under the pressure of expanding ice, PERT EVOH pipes can absorb the stress caused by freezing water. This flexibility is a key factor in their anti - freezing performance. For example, in a heating system during a cold winter night, if the water in the pipes freezes, the PERT EVOH pipes can stretch to accommodate the expansion of the ice, preventing catastrophic failures.

Low Thermal Conductivity

PERT has relatively low thermal conductivity, which means it doesn't transfer heat as quickly as some other materials. This property helps to slow down the freezing process of the water inside the pipe. When the external temperature drops, the low thermal conductivity of PERT acts as an insulator, keeping the water inside the pipe at a higher temperature for a longer period. In a building's plumbing system, this can be crucial in preventing the water from freezing during short - term cold snaps.

EVOH Barrier Function

The EVOH layer in PERT EVOH pipes not only provides an oxygen barrier but also contributes to the anti - freezing performance. EVOH has low water vapor permeability. This means that it can prevent moisture from seeping into the pipe wall from the outside environment. If moisture were to penetrate the pipe wall and freeze, it could cause damage to the pipe. By keeping the pipe wall dry, the EVOH layer helps to maintain the integrity of the pipe in freezing conditions.

Factors Affecting the Anti - Freezing Performance of PERT EVOH Pipes

Pipe Wall Thickness

The thickness of the pipe wall plays an important role in anti - freezing performance. Thicker walls can provide more structural support and better insulation. A thicker PERT EVOH pipe is more likely to withstand the pressure of expanding ice without cracking. However, it's important to balance the wall thickness with other factors such as cost and flow capacity. In some applications, a thicker - walled pipe may be necessary, while in others, a thinner - walled pipe may be sufficient.

Installation Conditions

Proper installation is crucial for the anti - freezing performance of PERT EVOH pipes. Pipes should be installed with adequate support and protection. For example, pipes should be insulated to reduce heat loss and prevent freezing. In addition, pipes should be installed at the correct slope to ensure proper drainage. If water is allowed to pool in the pipes, it is more likely to freeze and cause damage. In a large - scale heating installation, following the correct installation procedures can significantly improve the pipes' ability to withstand freezing conditions.

External Temperature and Duration of Cold

The severity and duration of cold weather also affect the anti - freezing performance of PERT EVOH pipes. In extremely cold regions with long - lasting freezing temperatures, additional measures may be required to protect the pipes. For instance, in arctic areas, pipes may need to be buried deeper underground or heated trace wires may need to be installed along the pipes to prevent freezing.

Testing the Anti - Freezing Performance of PERT EVOH Pipes

To ensure the quality and anti - freezing performance of our PERT EVOH pipes, we conduct a series of tests. One of the common tests is the freeze - thaw cycle test. In this test, the pipes are filled with water and subjected to repeated cycles of freezing and thawing. The pipes are monitored for any signs of damage, such as cracks or leaks. Our pipes have consistently passed these tests, demonstrating their ability to withstand the stresses of freezing and thawing.

Another test we perform is the burst pressure test at low temperatures. This test measures the pressure at which the pipe will burst when the water inside is frozen. Our PERT EVOH pipes have shown high burst pressure values at low temperatures, indicating their excellent anti - freezing performance.

Applications Where Anti - Freezing Performance Matters

Heating Systems in Cold Climates

In regions with cold winters, heating systems are essential for maintaining comfortable indoor temperatures. PERT EVOH pipes are widely used in these systems because of their anti - freezing performance. Whether it's a residential radiator system or a large - scale district heating system, the ability of these pipes to withstand freezing temperatures ensures reliable operation throughout the winter.

Outdoor Water Supply Systems

Outdoor water supply pipes are particularly vulnerable to freezing. PERT EVOH pipes can be used in these applications to prevent damage caused by freezing water. For example, in a garden irrigation system or a rural water supply network, PERT EVOH pipes can ensure a continuous water supply even in cold weather.

Conclusion

The anti - freezing performance of PERT EVOH pipes is a result of the unique properties of PERT and EVOH materials, as well as proper design and installation. Their flexibility, low thermal conductivity, and the barrier function of EVOH all contribute to their ability to withstand freezing conditions. Whether you're in the market for PERT/EVOH Pipe 3 Layers or PERT/EVOH Pipe 5 Layers, you can trust in the quality and anti - freezing capabilities of our products.

If you're interested in learning more about our PERT EVOH pipes or are looking to make a purchase, we encourage you to reach out to us. Our team of experts is ready to assist you with your piping needs and answer any questions you may have. Contact us today to start a fruitful procurement discussion.

References

- ASTM standards related to plastic pipes for hot and cold water distribution systems.

- Technical literature on PERT and EVOH materials from resin manufacturers.

- Industry reports on the performance of plastic pipes in cold climates.