How to install PE-Xa and copper fitting

Leave a message

Step 1.

Measure the pipe to the

correct length and using a

secateur-type pipe cutter,

cut the pipe squarely and

remove any burrs. The end

of the pipe may need to be

freshly cut to ensure smooth

passage for the fitting.

Do not use a hacksaw.

Step 2.

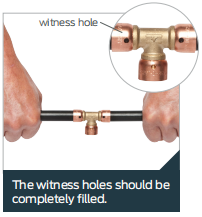

The pipe is pushed over the

barbed fitting and at the

same time under the crimp

ring. The fit should be firm.

If the joint feels sloppy or

hard to insert, check pipe

and fittings. Do not use

lubricants. Ensure the pipe

is visible in both crimp ring

witness holes.

Step 3.

Make sure the tool jaws are

centralised over the crimp

ring at 90° to the joint.

When using the manual tool,

close the tool completely to

compress the crimp ring.

The tool will click at final

compression.

When using a battery tool, ensure the tool has fully closed and released indicating a completed joint.

Step 4.

For manual tool use,

regularly check with the

gauge supplied by sliding

the opening of the gauge

over the compressed ring. If

the gauge passes over all

parts of the ring without

interference, then the

joint has been crimped

satisfactorily.

Correctly serviced battery

tools do not require a

gauge check if the joint has

been completed as per

instructions.

Step 5.

Pressure test the system in accordance with AS/NZS 3500 and with local requirements.