Tianjin Huilide New Materials is a trading company of Tianjin Minde Heating Equipment Co., Ltd. The company is located in the beautiful coastal city of Tianjin, covering an area of 10,000 square meters. Among the Chinese floor heating pipe manufacturers, the number of equipment ranks among the top three, and all of them are advanced production equipment, some of which are self-developed technologies.We're known as one of the most professional PEX EVOH pipe manufacturers and suppliers in China.

High Quality

All raw materials produced by Tianjin Minde are imported raw materials, such as: LGSL188, Lotte8100GX, Basell 3060, Sonarnol's A4412B, which guarantee the product stability and safety of the pipe to the greatest extent.

Advanced Equipment

We have 92 advanced PEXa pipe production lines, 5 PEXa oxygen barrier production lines, 2 PERT pipe production lines, 2 PEX-Al-PERT pipe production lines, and 10 injection molding pipe fittings equipment, with an annual production capacity of 100 million meters of pipes.

ODM/OEM Service

Our team of experts will work closely with you to understand your needs and will provide solutions that are tailored to meet your expectations.

Production Market

All pipes of our company have been exported to Russia, Australia, Brazil, the United States and other parts of the world, and have obtained access certificates such as Russian GOST , Australian watermark and US NSF certification etc .

Advantages of PEX EVOH Pipe

Oxygen Barrier Protection: The EVOH layer acts as an oxygen barrier, preventing the diffusion of oxygen into the water within the pipe. This is crucial because oxygen can corrode metal components and reduce the efficiency of the heating system.By blocking oxygen, EVOH pipes help extend the life of these components and reduce maintenance costs.

Flexibility: PEX EVOH pipes are known for their flexibility, making them easy to install, especially in complex and tight spaces. They can be bent and curved without the need for additional fittings.

Durability: PEX EVOH pipes are durable and resistant to chemicals and scaling, which ensures a long lifespan and minimal maintenance.

Energy Efficiency: Radiant heating systems with PEX EVOH pipes are highly efficient in terms of energy consumption and heat distribution, resulting in lower energy bills.

Compatibility: PEX EVOH pipes are compatible with various types of fittings and are suitable for direct burial and concrete installation.

Cost-Effective: PEX EVOH pipes are cost-effective both in terms of material cost and ease of installation, making them a popular choice for radiant heating applications.

Radiant Heating Systems

PEX EVOH pipes are commonly used in radiant floor heating systems. They distribute heated water throughout the system efficiently. The EVOH layer prevents oxygen from entering the pipe. This protects metal components from corrosion. The PEX material provides flexibility and easy installation, making it a good choice in providing warmth. It gives even heat distribution while keeping energy costs low.

Water Supply Lines

PEX EVOH pipes are also used in potable water supply lines. The EVOH barrier ensures that water quality is maintained by preventing contaminants from entering the system. PEX pipes are resistant to scaling and corrosion. This makes them advantageous over traditional metal pipes. Their flexibility allows easier installation in tight spaces, reducing the need for joints and giving a more reliable water supply.

Re-Modeling and Retrofits

There are old buildings that are re-modeled to make them useful again. PEX pipes are ideal for retrofitting existing plumbing systems. They are able to fit into tight spaces and navigate old infrastructure easily. The EVOH layer provides added protection to the system, ensuring longevity. Their use in re-modeling offers a cost-effective solution for upgrading the existing heating and water supply systems.

Snow Melting Systems

PEX EVOH pipes are used in outdoor snow melting systems for driveways and walkways. They circulate warm water throughout the pavement during snow and ice. This makes the snow melt quickly and keeps the surface safe. The oxygen barrier prevents pipe degradation. This ensures the system has a long lifespan and reliable performance even in harsh weather conditions.

Emergency Heat Transfer

PEX EVOH pipes are used to quickly transfer heat in emergency heating applications. They help maintain desired temperatures in areas of low heat demand. The oxygen barrier keeps the water safe from contamination. This maintains the efficiency of the heating system during emergencies.

|

Specification |

||||||

|

Material |

PE |

|||||

|

Production standard |

ASTM F876/877, ISO15875, AS/NZS2492,etc |

|||||

|

Thickness |

1.8-5.4mm or as request |

|||||

|

Length |

50-300M/Roll or according to your requirements |

|||||

|

Color |

Natural,Orange, White or Customized |

|||||

|

Physical and chemical characteristics of PEX EVOH Pipe |

||||||

|

Item |

Requirements |

Test Time |

Test temperature |

Hoop Stress |

||

|

Longitudinal Reversion |

≤3% |

1h(en≤8mm) |

120℃ |

___ |

||

|

Hydrostatic Stress Test |

No Bursting No Leakage |

22h 165h 1000h |

95℃ 95℃ 95℃ |

4.7Mpa 4.6Mpa 4.4Mpa |

||

|

Thermal Stability |

No Bursting No Leakage |

8760h |

110℃ |

2.5Mpa |

||

|

Cross-linking Degree |

≥75% |

___ |

___ |

___ |

||

Compatibility with Other Materials: When installing PEX EVOH pipes, it’s important to ensure they are compatible with other materials in the system, such as fittings, connectors, and insulation. This compatibility is crucial to avoid chemical reactions that could degrade the pipe or compromise the system’s integrity.

Proper Handling During Installation: Although PEX EVOH pipes are durable, they should be handled with care during installation to avoid damaging the EVOH layer. Scratches or cuts in the pipe can compromise the oxygen barrier, leading to potential issues down the line.

Pressure and Temperature Ratings: Ensure that the PEX EVOH pipes selected for a particular application meet the required pressure and temperature ratings. This is particularly important in heating systems where high temperatures and pressures are common.

Process of PEX EVOH Pipe

Raw material preparation

Polyethylene resin for the PEX layers and EVOH resin are carefully dried and mixed to ensure consistent quality.

01

PEX extrusion

The HDPE is melted and extruded through a die to form the inner and outer PEX layers.

02

EVOH co-extrusion

Simultaneously, the EVOH is extruded as a thin layer between the PEX layers through a specially designed crosshead that precisely controls the thickness and placement of the barrier layer.

03

Cross-linking

The PEX layers undergo a cross-linking process, usually using the peroxide (Engel) method, where chemical bonds are created between the polyethylene molecules to improve the pipe's strength and durability.

04

Cooling and sizing

The extruded pipe is cooled and precisely sized through a sizing die to achieve the desired diameter.

05

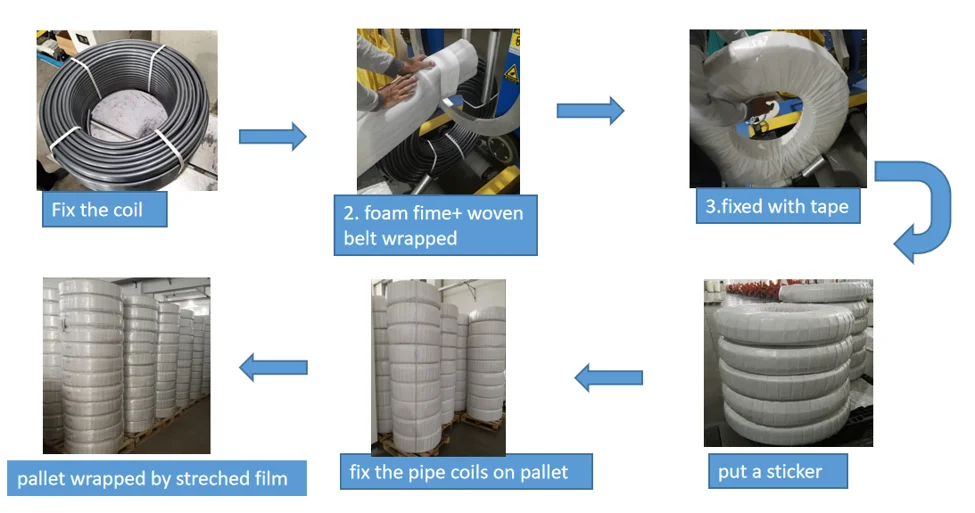

Packing & Delivery

Our Certificates

FAQ

We're well-known as one of the leading PEX EVOH pipe manufacturers and suppliers in China. Please rest assured to buy customized PEX EVOH pipe at competitive price from our factory. For quotation, contact us now.

Pex pipe system, PEX EVOH Pipe, PEX tubing for radiant heating