Tianjin Huilide New Materials is a trading company of Tianjin Minde Heating Equipment Co., Ltd. The company is located in the beautiful coastal city of Tianjin, covering an area of 10,000 square meters. Among the Chinese floor heating pipe manufacturers, the number of equipment ranks among the top three, and all of them are advanced production equipment, some of which are self-developed technologies.We're known as one of the most professional PERT pipe manufacturers and suppliers in China.

High Quality

All raw materials produced by Tianjin Minde are imported raw materials, such as: LGSL188, Lotte8100GX, Basell 3060, Sonarnol's A4412B, which guarantee the product stability and safety of the pipe to the greatest extent.

Advanced Equipment

We have 92 advanced PEXa pipe production lines, 5 PEXa oxygen barrier production lines, 2 PERT pipe production lines, 2 PEX-Al-PERT pipe production lines, and 10 injection molding pipe fittings equipment, with an annual production capacity of 100 million meters of pipes.

ODM/OEM Service

Our team of experts will work closely with you to understand your needs and will provide solutions that are tailored to meet your expectations.

Production Market

All pipes of our company have been exported to Russia, Australia, Brazil, the United States and other parts of the world, and have obtained access certificates such as Russian GOST , Australian watermark and US NSF certification etc .

Advantages of PERT pipe

Flexibility: PERT pipes are highly flexible and offer a range of installation options. They can be bent and curved to fit the contours of any space, making them ideal for complex installations with tight corners and limited access.

Corrosion resistance: PERT pipes are highly resistant to corrosion and rust, which makes them ideal for use in areas with high moisture levels. They do not deteriorate over time, helping to prolong the lifespan of the entire piping system.

Thermal resistance: PERT pipes are designed to withstand high temperature fluctuations without cracking or deforming. They can handle both hot and cold water temperatures, making them perfect for use in a wide range of domestic and commercial applications.

Low installation costs: PERT pipes are relatively easy to install, which reduces the overall installation costs. Their flexibility allows for speedy installation, reducing the downtime in projects.

Easy to maintain: PERT pipes require little maintenance over their lifespan. Unlike traditional copper pipes, they do not corrode and do not require regular pipe replacements.

Energy efficiency: PERT pipes are highly energy-efficient, thanks to their superior insulation properties. They help to reduce heat loss, which can translate into lower energy consumption in homes and buildings.

Safe for drinking water: PERT pipes are approved for use in potable water supply systems. They do not contaminate water with harmful substances and are safe for drinking.

Plumbing Systems

PERT pipes are used in both residential and commercial plumbing systems for the distribution of hot and cold water. They offer excellent resistance to corrosion, scaling, and chemical degradation.

Radiant Floor Heating

PERT pipes are widely used in radiant floor heating systems. These systems use hot water circulated through PERT pipes installed on the floor to provide efficient and comfortable heating.

Potable Water Distribution

PERT pipes are suitable for use in potable water distribution systems. They are resistant to chemical reactions, making them a safe choice for conveying drinking water.

Hydronic Heating Systems

PERT pipes are used in hydronic heating systems, which utilize hot water or steam to provide heating in residential, commercial, and industrial settings.

Snow Melting Systems

PERT pipes are used in snow melting systems, where they are installed beneath driveways, walkways, or other surfaces to circulate warm water or antifreeze, melting snow and ice.

Industrial Applications

PERT pipes find applications in various industrial processes, such as transporting chemicals, acids, and other fluids where resistance to corrosion and high temperatures is required.

|

Specification |

|

|

Material |

PE |

|

Production standard |

ISO22391, GB/T28799, DIN4721 |

|

Thickness |

1.8-5.4mm |

|

Length |

100-300M/Roll or as request |

|

Color |

Natural,Orange, White or Customized |

|

Physical and chemical characteristics of PERT pipe |

|

|

Density |

0.93-0.94g/cm³ |

|

Thermal conductivity |

0.4W/m▪K |

|

VICAT Softening temperature |

122-123℃ |

|

Maximum temperature of function |

95℃ |

|

Coefficient of linear thermal expansion |

0.19Mm/m°K |

Raw Materials for PERT Pipe Production

The manufacturing process begins with the selection of high-quality raw materials:

● Polyethylene Resins: The primary material used, specifically designed to withstand elevated temperatures.

● Additives: These include antioxidants, UV stabilizers, and colorants that enhance the properties of the final product.

Compounding Process

Before the extrusion of PERT pipes, the raw materials are compounded:

● Mixing: The polyethylene resin is mixed with additives to achieve the desired properties.

● Melt Processing: The mixture is heated until it reaches a molten state, ensuring uniform distribution of additives.

Extrusion Process

● Feeding: The compounded material is fed into an extruder, where it is heated and forced through a die.

● Molding: As the molten material exits the die, it takes the shape of a pipe. This stage requires precise control of temperature and pressure to ensure uniform thickness and quality.

Cooling Process

Once the PERT pipe is extruded, it undergoes cooling:

● Water Cooling: The pipes are typically cooled in a water bath to solidify the material and maintain its shape.

● Air Cooling: In some cases, air cooling may be used, depending on the production line setup.

Cutting and Sizing

After cooling, the pipes are cut to the required lengths:

● Automatic Cutting Machines: These machines ensure consistent lengths and minimize waste.

● Quality Control Checks: Each length is checked for dimensional accuracy before packaging.

Quality Assurance Testing

● Physical Testing: Pipes undergo tests for flexibility, tensile strength, and resistance to pressure.

● Thermal Testing: Assessing the performance of the pipes under elevated temperatures to ensure compliance with industry standards.

Surface Treatment and Printing

To enhance the usability of PERT pipes, additional treatments may be applied:

● Surface Treatment: This can involve smoothing or coating the pipes for better handling.

● Printing: Identification marks, such as size and material type, are printed on the pipes for easy identification and compliance with regulations.

Packaging and Distribution

Once manufactured and tested, the pipes are prepared for distribution:

● Packaging: Pipes are bundled and packaged to prevent damage during transportation.

Planning and Preparation

Begin by mapping out your plumbing system. Identify areas where PERT pipes will run and position fittings, connectors, and any necessary valves. Measure and mark the required pipe lengths using the measuring tape.

Cutting and Deburring

Use a pipe cutter to cut the PERT pipes to the measured lengths. Ensure the cuts are straight and clean. After cutting, use a deburring tool to smooth the edges of the pipe ends, removing any burrs that may cause leaks or blockages.

Assembling the Pipes

Insert fittings and connectors into the pipe ends. Ensure they are compatible with PERT pipes to create secure and leak-free joints. Use wrenches to tighten the fittings as per the manufacturer’s recommendations.

Securing the Pipes

Attach clips or brackets at regular intervals along the pipes to prevent sagging. Ensure the pipes are firmly positioned and supported, reducing stress on joints and connections.

Connecting to Fixtures

Connect the assembled PERT pipes to the plumbing fixtures or appliances. Double-check all connections to ensure they are tight and properly sealed.

Pressure Testing

Use a pressure testing kit to check for leaks. Gradually pressurize the system to the recommended operating pressure and monitor for any drops in pressure. Address any leaks immediately by tightening or reassembling the affected joints.

Insulating (if required)

If additional thermal protection is needed, wrap the pipes with insulation tape, particularly in areas susceptible to temperature fluctuations.

Final Check

Once everything is installed and tested, conduct a final check of the entire system. Ensure all connections are secure, the pipes are properly supported, and there are no visible leaks or defects.

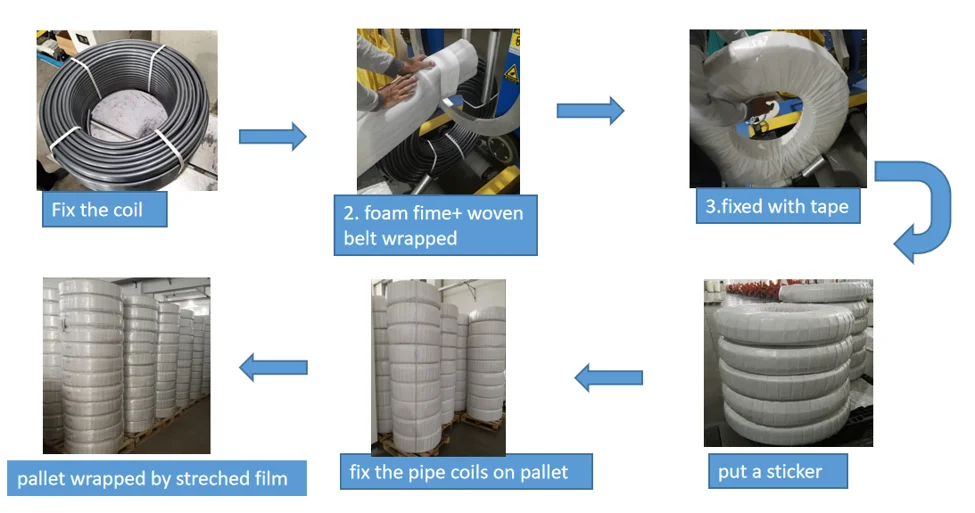

Packing & Delivery

Our Certificates

FAQ

We're well-known as one of the leading PERT pipe manufacturers and suppliers in China. Please rest assured to buy customized PERT pipe at competitive price from our factory. For quotation, contact us now.

PERT for floor heating, PERT Tube, polyethylene PERT pipe